Ever wonder how to go from idea to an actual touchable prototype? In this blog post, I will detail my journey from having an idea and mission to creating an actual prototype.

This blog post is in a journal style and documents my journey creating the first prototype.

About Wheelies

Wheelies is a shoe company with the goal of creating shoes that consist of a sole from used tires. Due to the growing amount of non-biodegradable tires in landfills, more toxins are being released into the atmosphere. Our mission is to lower the number of landfill tires by repurposing them.

First Model

When Wheelies started, we came across the idea to create a shoe by repurposing tires which intoxicate our atmosphere. The idea originated from our cousin, Allen Do Rosario, who was an executive in the tire industry.

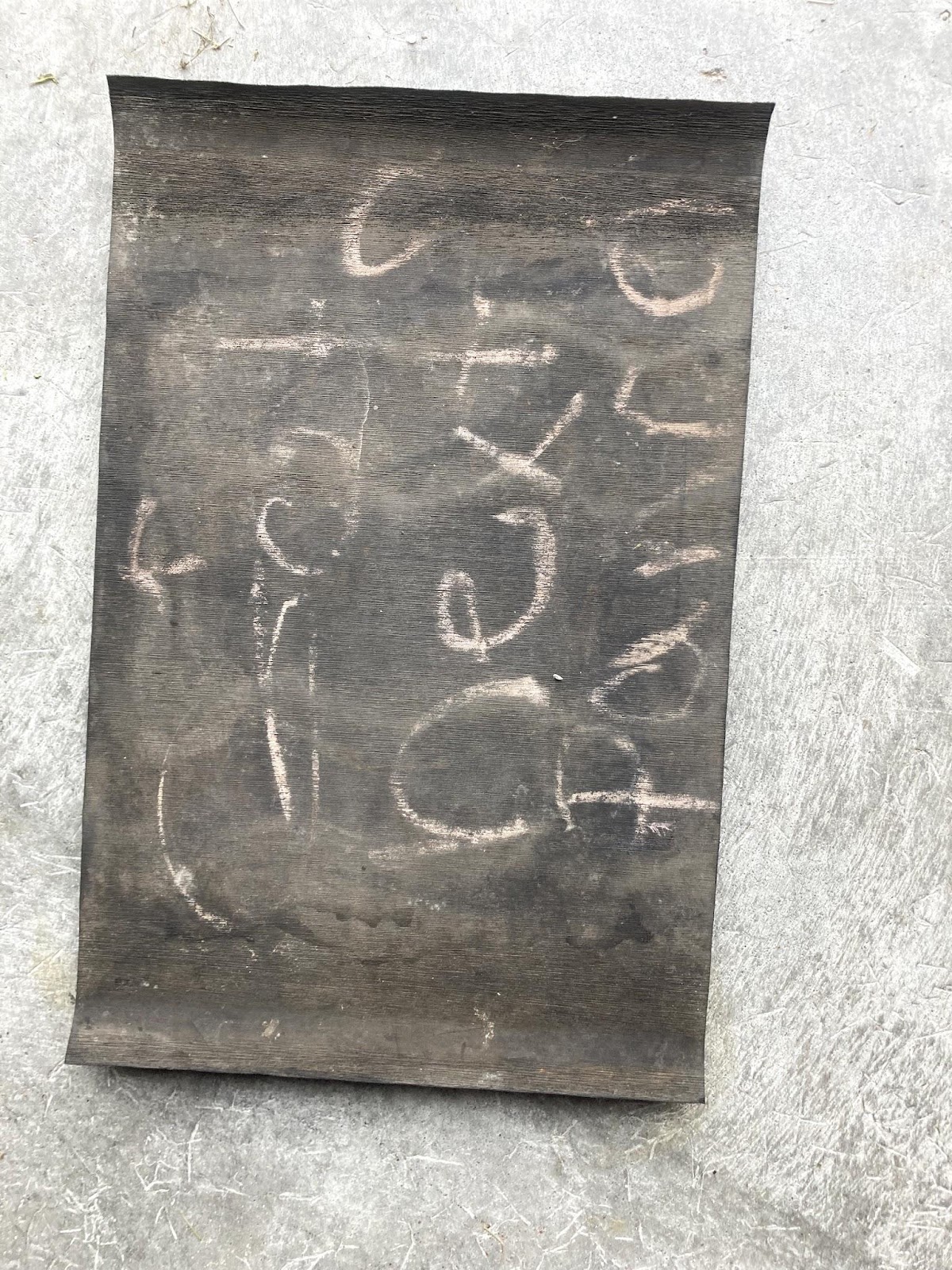

The above prototype was envisioned and drawn by my baby sister, Danika Do Rosario, then in 3rd grade. It ignited the process to compete in the Shark Tank competition.

This mission is what led our pitch in the Holliston Shark Tank Competition, run by a group known as Team Eric. Our pitch is shown below.

Prototyping Process

After winning the competition and receiving funds ($500) from Team Eric’s Shark Tank competition, we embarked on a journey to create our first prototype of the shoe.

(2/26/21) First we created the design of the shoe, which was a sandal that consisted of a sole of a recycled tire. Where and how we would get the tires and create the sole and the shoe in general was unknown. Nevertheless, we pitched the idea, with our goal to create a shoe that repurposed used tires. We would use the funds to create the shoe.

(7/6/21) After receiving funding, over the summer we began the process to create the first prototype. However, we were stuck on exactly where to begin. We thought that in order to create a shoe, we should talk to shoe people. With that said, we went to Cobbler Shop West in Natick, MA seeking some answers from the cobbler. He told us he couldn’t make an entire shoe from scratch or create it from a tire. Furthermore, he didn’t know anybody who did know what we asked. However, he explained to us that if we brought a shoe and the tire sole, he could glue it all on to create a shoe with the tire sole.

(7/6/21) With this in mind, we sought to find a shoe that fit our model in mind. After a few thrift shop stores, we selected a few pairs at Savers that could easily be paired with a tire sole (the cobbler said the sole had to be flat).

After finding some shoes, we cut a tire we had, separating the sides from the body of the tire. We used a pocket knife and lubricant. After isolating the overall middle of the tire, we needed to make a cut through it to lay it down in a row, but as we found out later, a metal belt that runs through the interior prevented us from cutting through a cross-section.

We tried taking the tire to the cobbler again, but he didn’t have the tools to cut through the tire’s metal belt. He suggested a tire disposal or auto body shop.

We looked up tire disposals, but none were nearby. However, after calling and visiting many auto body shops, we were led to Pete’s Tire Barn in Shrewsbury, MA. Patrick, their manager, told us he could possibly give us the “skin” of the tire, which is the part without the metal that the cobbler needed.

(8/16/21) When we came to Pete’s, we learned that we needed the tread of a tire, which is basically the outer rubber parts of the tire. In industry lingo, this is called the “cap retread”. Patrick informed us that he had some tread rubber and gave us a slab that could be the sole of at least one shoe. He also informed us he got his tread from their distribution center in Orange, MA or Rutland, VT, where the used tires’ tread is shaved/buffed and then retreaded (How This Works). When a large 18-wheeler tire needs to be retreaded, the US govt has mandated that instead of buying a new tire, the tire should be first retreaded. In this process, the outer tread of a tire is shaved/buffed and replaced with a fresh rubber-only retread called the “cap retread”.

Next Steps: We are right now hoping that we can get a hold of some “cap retread” tire tread from this place or their used tire tread to keep alive the goal of repurposing tires.

We took the tread that Pete’s tire barn gave us, and using a heel-flp-flop pair, the natick cobbler attached the tread, the full thickness, onto the shoes. Despite its amazing look, walking on it was like walking on bricks.

Second Model

When we called my dad’s cousin, Allen, who works at Bridgestone, the tire brand, he told us that we had used truck tire tread with the cobbler. Even though it looked so thin, it was actually once parts of a tire. Allen told us we should use a passenger tire, and we can see if a tire is a passenger tire by using the penny test on the tread. Allen also told us he would send us a striped down passenger tire tread from a lab in Ohio.

After receiving Allen’s tire tread, we went to the natick cobbler. His associate was working, but told us that the cobbler could still do it. We wanted to use the blue and tan shoes (not sandals) from the picture above.

To make sure our original cobbler (not his coworker) was clear on this new task, we visited a week later on a day when we knew the cobbler was in. He was quite annoyed, in fact, because his coworker and we had trimmed some off the foundation of the original sole of the brown shoes we intended to use. We asked if he could simply disregard the old sole and replace all of it with the tread, to which he replied yes, but was still annoyed and pessimistic of this task.

After about a month, we visited the Natick cobbler again. Both he and his companion were working due to the increase in demand during the holidays. Luckily, he had finished the shoe. This time, it felt very comfortable. The upper part of the shoe, without the sole, was still a worn out shoe, so I put in my insole I wear regularly to walk in these “workman boots” as papa calls them. To our great surprise, they were fantastic to walk or run in.

In order to know how these tire boots will feel, I needed to “be the fish” or wear them in my normal life. Therefore, for the last two days of school before Christmas break, I wore them around school. The shoe itself was big on me, so therein lies some error, but with a strong, firm tying, they were secure. I actually got many compliments, but they were likely for the shoe itself and not primarily the sole. However, the fact that we got compliments indicates that people would likely be interested in these shoes not only for its environmental purposes, but just its style if we choose to pursue this path. Walking in the shoe was also a breeze. I had to walk all around my school, often staying at the school till 7 on these two days. Never did I feel any discomfort. I ran across the football field. Nothing.

Next Steps

(12/22/21): It seems that we know that this idea is possible, for we can tangibly see or wear our shoes. Now we must find out many questions, including,

How will we get enough tire tread for production?

What will the top half of the shoe look like?

- What type of shoe are we targeting?

- Which colors?

- Who will make this top half

Can the manufacturers create a shoe with the tread, even if we have it all available?

What community are we targeting?

- Are we going for style (like Nike) or mission (like Allbirds)?

- Kids?

- Environmentalists?

Will the general public accept or reject our first products?

Conclusion

This is the journal for the initial two prototypes. Follow along our journey, as we then went from prototype to producing the first batch of 10 shoes.